Vanadium Resources - What is Vanadium Pentoxide?

What is Vanadium?

Vanadium pentoxide is a silver-grey ductile and malleable metal that has a natural resistance to corrosion and stability against alkalis, acids and saltwater. This unique mineral is classified by the Australian Government as a ‘Critical Mineral’ and is strongly backed and supported by Federal and Queensland Governments. These vanadium resources will play a vital role in the development of a new energy economy.

“The most beautiful metal of all”…

Vanadium pentoxide isn’t found in its metallic form but rather in more than 60 minerals as a trace element in a range of rock types. Vanadium resources may be found in magnetite (iron oxide), aluminium ore, sandstone, coal or oil shale. Once Vanadium is extracted and dissolved in water, it transforms into several bright shades of the rainbow, thus being described as “the most beautiful metal of all”.

Vanadium Demand Outlook

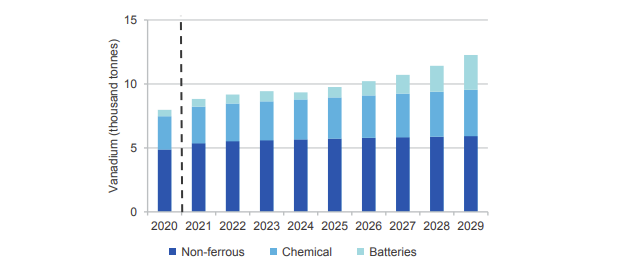

Vanadium market participants are becoming increasingly bullish in their outlook on Australian Vanadium ASX demand and prices, anticipating growth from both traditional and emerging end-use bases. There is an increasing global demand for lighter-weight and higher-strength steel, as well as increasing global demand for renewable and reliable energy, making vanadium pentoxide a valuable metal. The vanadium resources market is predominantly driven by steel usage, accounting for 90% of vanadium consumption. As depicted in Figure 1 Below, the steel market is projected to grow by an average of 2.9% a year between 2020 and 2029. Additionally, as previously mentioned, emerging low‑emissions technologies are playing an increasing role in vanadium consumption. As such, the Vanadium consumption for batteries is forecast to grow at an average of 20.7% a year from 2020 to 2029.

A global squeeze…

Currently, the world vanadium market is experiencing a market squeeze with steel production at record levels and record vanadium flow battery announcements. Further accompanying this strong market demand are recent regulatory shifts in China, where rebar strength is now raised to Grade 3, ultimately requiring an increase in the level of vanadium resources in construction metals. Market shortfalls are likely to continue to occur over the next couple of years, as Chinese steel production continues to grow. Price forecasts suggest that market shortfalls will result in a tighter market over the short to medium term. As new production begins to enter the market, prices are expected to return to a baseline (Figure 3).

As an Australian Vanadium ASX listed company, Critical Minerals Group is very well positioned to capture the present momentum of the vanadium market, with the Lindfield Project’s existing drillings showing strong promise.

Figure 1: Projected vanadium consumption by end use – including steel

Source: Roskill (2020); Department of Industry, Science, Energy and Resources (2021)

Figure 2: Projected vanadium consumption by end use – Excluding steel

Source: Roskill (2020); Department of Industry, Science, Energy and Resources (2021)

Figure 3: Vanadium Prices Outlook

Source: Roskill (2020); Department of Industry, Science, Energy and Resources (2021)

Vanadium Use Applications

-

Steel

The construction sector is the largest consumer of steel products. Vanadium pentoxide is highly sought after in this sector as Vanadium is an important alloying element that improves the strength, toughness, ductility, and heat resistance of steel. This safe, reliable and cost-effective solution for reinforced concrete construction is particularly favourable in the world’s earthquake-prone regions.

-

Master Alloys

Metal vanadium is used in the form of titanium-aluminium-vanadium alloys for aircraft engines, aerospace cabin frameworks, missiles, steam turbine blades, rocket engine shells, etc.

-

Oil and Gas Pipelines

High-strength, tough and weldable HSLA plate and coil steels containing vanadium resources are widely used for oil and gas transmission pipelines.

-

Vanadium Redox Flow Batteries

The production of Vanadium Redox flow batteries creates a reliable, safe and stable solution for the storage of renewable energy. These low-charge-time, lightweight batteries are the most efficient battery technology suitable for utility-scale renewable energy storage for both wind and solar.

-

Electric Vehicles (EV's)

Whilst the usage of Vanadium pentoxide in Lithium-Ion Batteries for EV’s is not yet significant, studies suggest as the transportation theme electrifies, its importance will grow. Vanadium-lithium batteries offer increased range/capacity from traditional technology, whilst also reducing carbon and weight.

-

Hand Tools

Chromium vanadium steel is an alloy tool steel with chromium (Cr) and vanadium (V) alloy elements. It has better strength and toughness than carbon steel, so it is a great material for high quality tools. Examples include wrenches, screwdrivers and manual sleeves.